PRODUCTS

- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

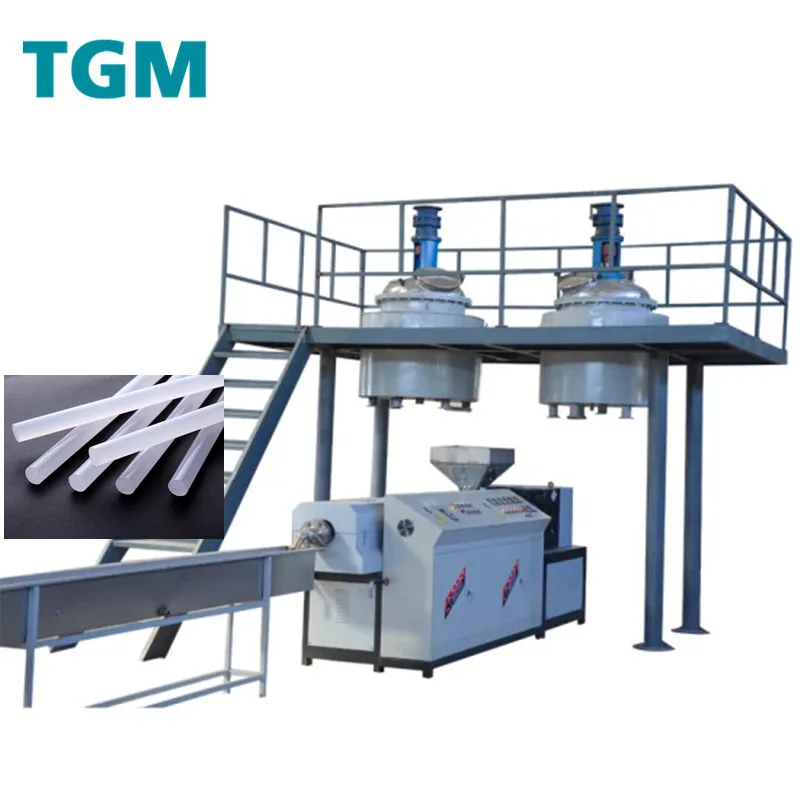

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

The field is required.

Automatic Powder Coating Full Production Line

Other recommendations

Key attributes

Industry-specific attributes

Power (kW)

80

Capacity

1000

Other attributes

mixer type

ribbon mixer

material processed

Powder

weight (kg)

30000

product type

Powder

voltage

220V, 380V, customized

warranty

1 Year

material

SUS304, Carbon Steel

additional capabilities

Milling

place of origin

Guangdong, China

brand name

TGM

key selling points

Automatic, Easy to Operate, High Productivity

machinery test report

Provided

video outgoing-inspection

Provided

core components

motor, Gear

Packaging and delivery

Selling Units:

Single item

Overview

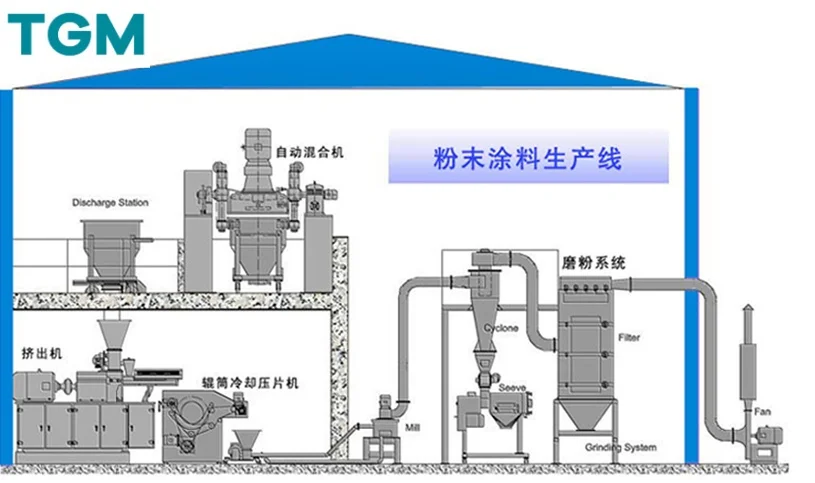

Semi Automatic powder coating Production Line in Small and Large Scale Capacity

step one: HLJ series high speed mixer is suitable for mixing multi-component granular or block solid materials. Under the combined action of stirring paddle and crushing wheel, the materials are stirred and mixed.

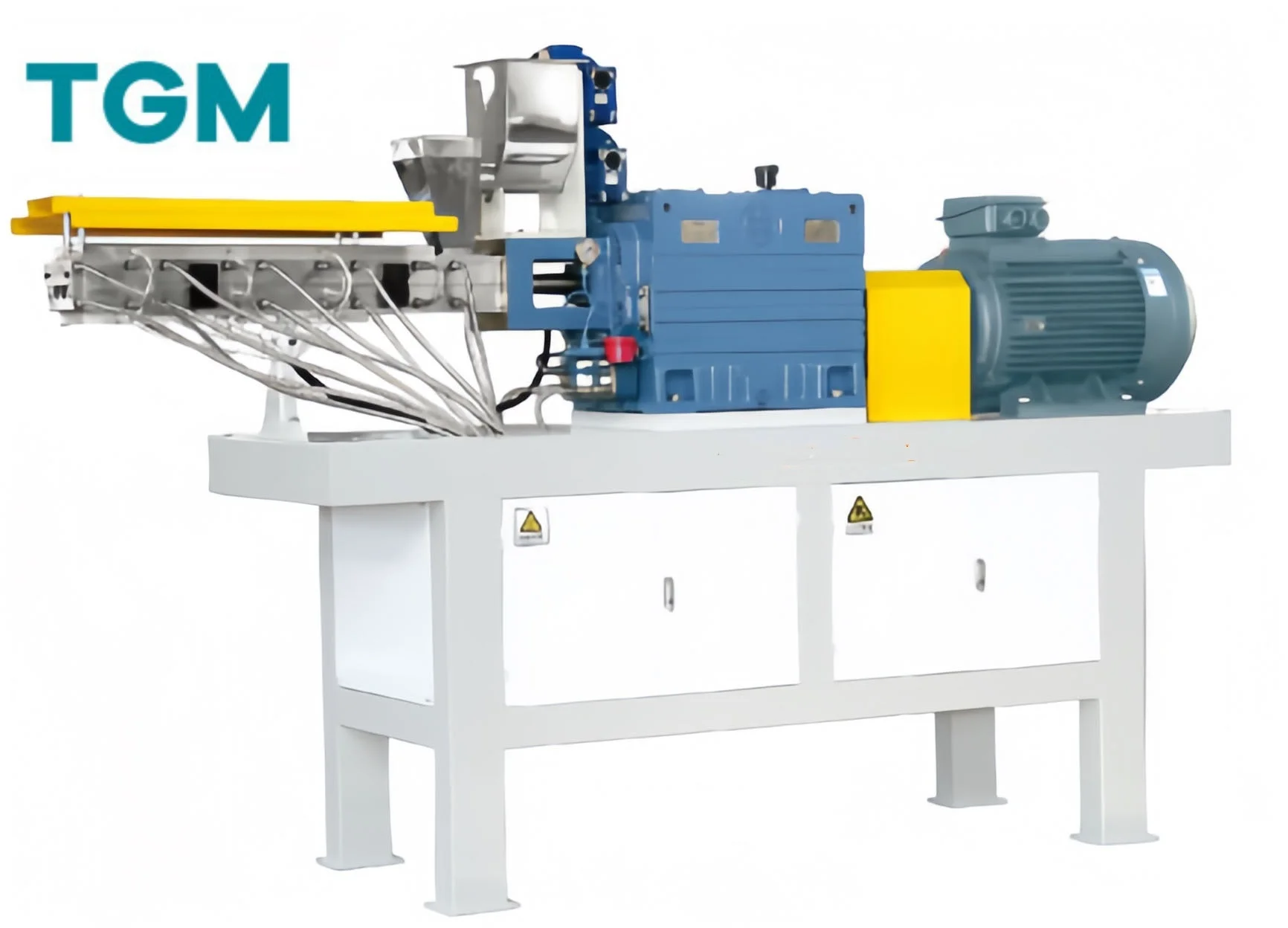

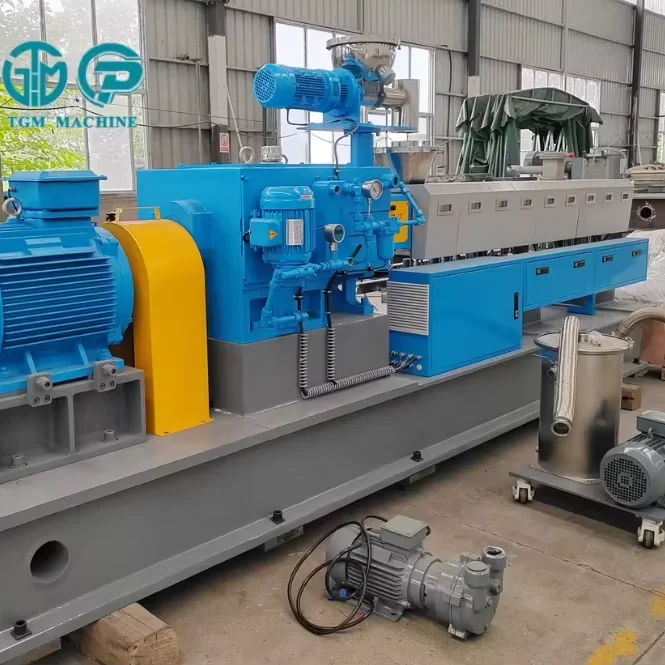

step two: TSK series high-performance twin-screw extruders are all of the same rotating structure, and the raw materials are fully dispersed and distributed under the action of high-speed rotating secret mixing block.

step two: TSK series high-performance twin-screw extruders are all of the same rotating structure, and the raw materials are fully dispersed and distributed under the action of high-speed rotating secret mixing block.

step three:Cooling band of series YPJ is composed of cooling-sheeting rolls, knotty stainless steel band conveyor and crusher. The kneaded thermal materials output from extruder is sheeted at thickness of 1-2mm. The rolls are cooled by water and air. The sheeted tape material is transported to crusher and cooled by fans continually. The crushed chip material falls down to the hopper.

step four: ACM is designed with high speed grinding air classifying, cyclone, sifting and fine powder collecting. A perfect particle size distribution of powder coating could be obtained by adjusting the running parameters of the grinding system.

step four: ACM is designed with high speed grinding air classifying, cyclone, sifting and fine powder collecting. A perfect particle size distribution of powder coating could be obtained by adjusting the running parameters of the grinding system.

Our Advantages:

1. Customized Flexible Production Capacity

2. Fully explosion proof machines provided

3. One stop pants production line machines supply

4. With plant panning service

5. Could Provide installation

6. Easy maintenance machines

7. Plenty of paints and coatings production line experience and projects

TGM Machine is professional in chemical machinery and complete production lines,with 19 years of industry experience.We integrate,design,development, production, sales and trading, maintenance together.We are a leader of this industry. Our company has professional R&D design team, strong technical support, skilled production team, reliable after sales service,flexible customized solutions, to meet your various standards and non standard equipment procurement needs.We committed to providing the complete and professional chemical equipmentsolutions.Our Main business scope: Disperser, Bead Mill, Mixer, Reactor, Filling machine, Bag filter, diaphragm pump, Zirconium bead, 3 roll mill, and other accessories.

Our machines help to make paints,coatings inks pigments, dyes, glues, adhesives,spin finish,wood glue,glue for paper conversion,viscous pastes, concrete Admixtures, PCVC solvent cement,resins ,sealants,silicone sealant, putty, lithiumbattery , electronic slurry&paste,pulps,liquid rubber,pesticide,liquid fertilizer, disinfectant,liquid detergent, lotions, shampoo, body wash liquid soap, hand sanitizer,nail polish,gel,creams,and other chemical and cosmetics products.

1.Are you a factory or a trading company? where is your factory?

-We are a real factory. Our factory is in fu'an industrial zone, leliu street, shunde ditrict, foshan city, guangdong province,China.

2. What are advantages of your factory?

-1)Our factory is a leader manufacture of Chemical machine With 19 years of Industry experience. We have a lot Technology Patents & Product Patents;

2) Our factory has Professional R&D Teams, High Technical Supports, Skilled Production Team, Reliable After Sales Service, Flexible Customized Solutions;

3) Our factory is the leader of this industry, named with high and new technology enterprise;

4) Our factory has plenty of industry experience, we could offer you the complete palnt planning.

3.Who are your factory's clients? Could you list some of them?

-AKZONOBEL, JUNTON, PPG, NIPPON, DABAO, BURGER, MAYDOS, RAINBOW, HITECH COATING, CHINA PAINT, CHANGJIANG COATING, TOA, LYNWON PIGMENT, PEONY INKS, TL INKS, ZR INKS, SAKATA INKS, KINGSWOO INKS, DIC INKS, ANLI, ACHILLES, REPOW GROUP, SHINETSU ADHESIVES, JUSHI, XINGLONG PESTICIDES, BYD, CATL...

4.Which countries your machine sold to?

-American Market: America, Canada, Mexico, Brazil; -European Market: UK, Germany, Netherlands, Bulgaria, Italy, Russia; -African Market: South Africa, Algeria, Zambia, Cameroon, Ethiopia, Uganda, Madagascar; -Asian Market: Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Bangladesh, India, Pakistan, Lebanon, Iraq, Qatar, Turkey, Saudi Arabia, UAE;

5.Could your factory provide formula and raw materials service?

-.Basically we are machinery suppliers, not products chemist. For some paint&coatings, silicone sealant, textile printing adhesives or pesticide we could help you find chemist and raw materials from our cooperative clients. Other products we are not sure. But if you need our help, we will try our best to dicuss with our serviced cleints and see if they would like sell to you formula or not.

6.Do you have agent in our country?

-1.No, we ship directly from China to you. our machines generally ship without dismounting. You generally only need to connect electricity, you could use directly. If need installation, we provide detailed installation instruction for full line or we send engineers to help you with paying.

7.What's the payment method?

-We accept T/T and L/C payment.

- Tel:

-

Email:

INQUIRY

Certifications

SUBSCRIBE

INQUIRY