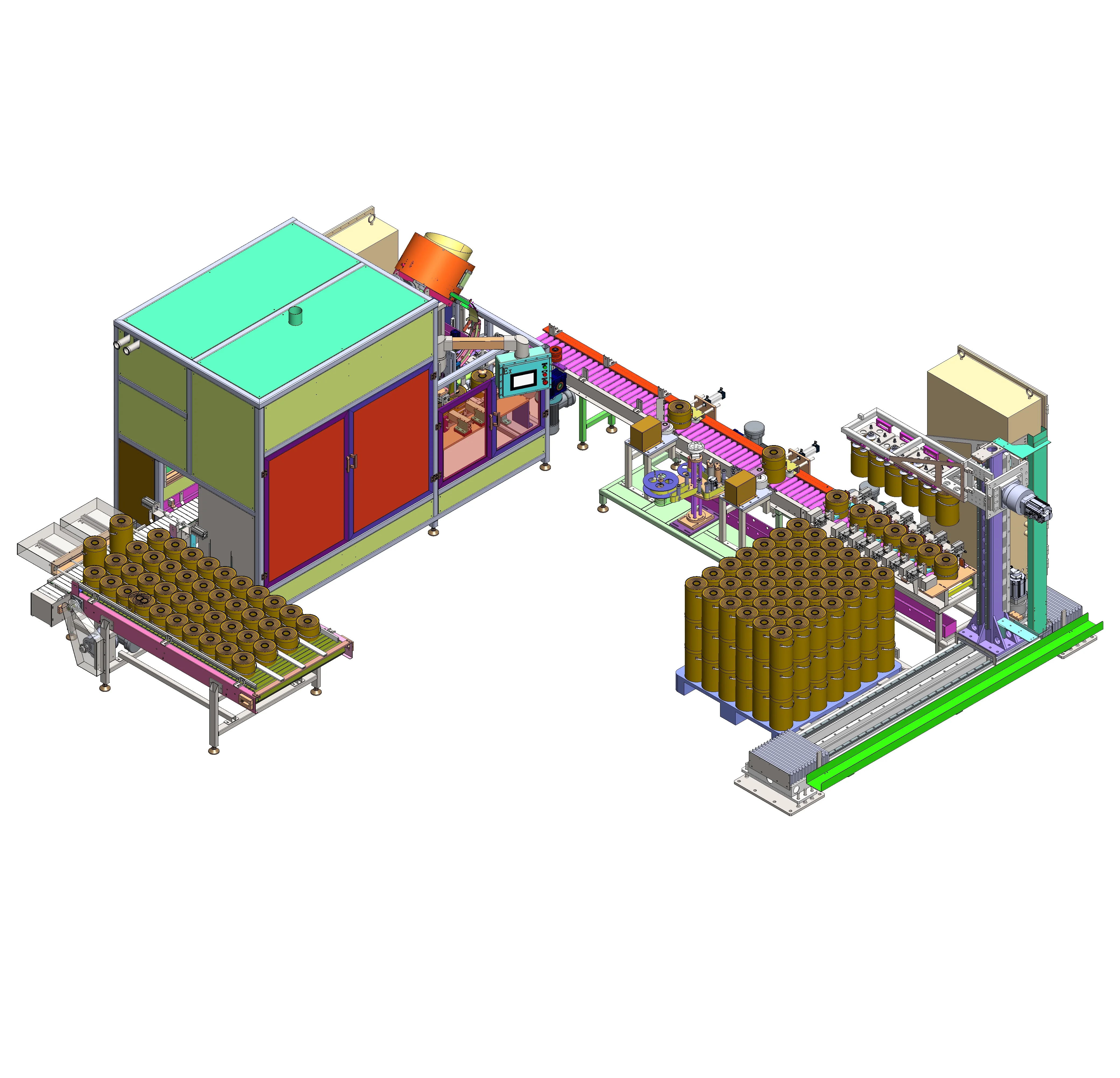

- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

ABOUT

TGM Machine is a leading supplier in the field of chemical machine industry. We are a group company with 19 years of industry experience. We located in Guangdong and Hunan province.

Our main products include kinds of mixer, bead mill, reactor, filter and filling machine. Our machines are widely use to make different products, for example paints, coatings, putty, inks, pigments, dyes, thinner, hardener, emulsions, varnish, glues, adhesives, resins, RTV, HTV, silicone sealant, MS sealant, PU sealant, lithium battery, electronic slurry&pastes, pulps, grease, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on. We are professional supplier for one stop solution of your full lines too.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions, to meet your various standards and non standard equipment procurement needs. We integrate design, development, production, sales, installation and training together. In addition, we have obtained kinds of certificates, such as ISO9001, ATEX, CE and so on.

Till now we have customers from more than 60 countries, such as UK, Spain, Italy, Germany, Netherlands, Bulgaria, Romania, Serbia, Cyprus, Russia, Belarus, Ukraine, America, Canada, Mexico, Brazil, South Africa, Algeria, Zambia, Kenya, Zambia, Cameroon, Ethiopia, Uganda, Madagascar, Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Uzbekistan, Tajikistan, Bangladesh, India, Pakistan, Lebanon, Iraq, Egypt, Qatar, Yemen, Oman, Turkey, Saudi Arabia, UAE and some other countries.

PRODUCTS

Precautions when operate the silicone sealant making machine

SUBSCRIBE

INQUIRY