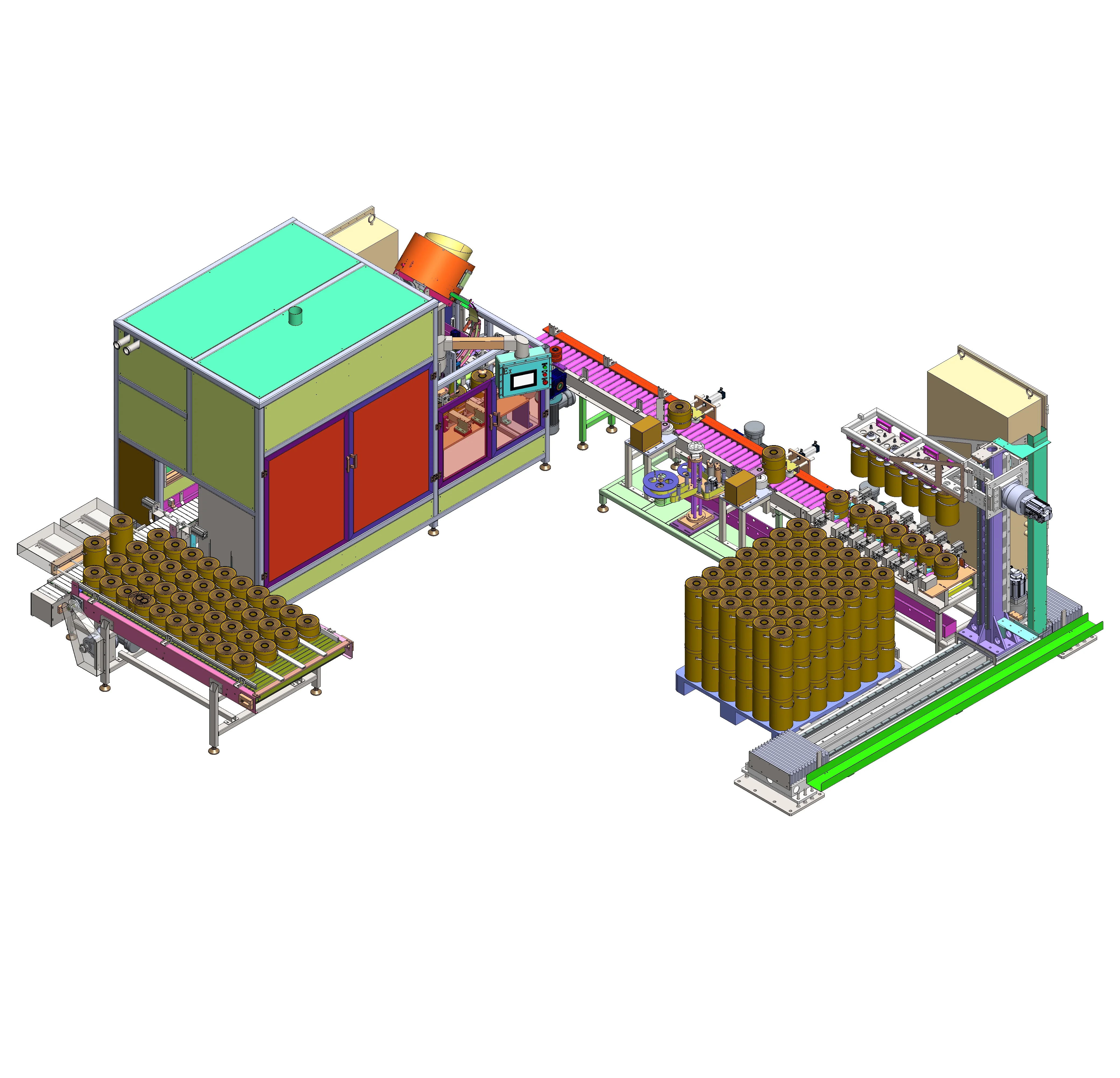

- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

ABOUT

TGM Machine is a leading supplier in the field of chemical machine industry. We are a group company with 19 years of industry experience. We located in Guangdong and Hunan province.

Our main products include kinds of mixer, bead mill, reactor, filter and filling machine. Our machines are widely use to make different products, for example paints, coatings, putty, inks, pigments, dyes, thinner, hardener, emulsions, varnish, glues, adhesives, resins, RTV, HTV, silicone sealant, MS sealant, PU sealant, lithium battery, electronic slurry&pastes, pulps, grease, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on. We are professional supplier for one stop solution of your full lines too.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions, to meet your various standards and non standard equipment procurement needs. We integrate design, development, production, sales, installation and training together. In addition, we have obtained kinds of certificates, such as ISO9001, ATEX, CE and so on.

Till now we have customers from more than 60 countries, such as UK, Spain, Italy, Germany, Netherlands, Bulgaria, Romania, Serbia, Cyprus, Russia, Belarus, Ukraine, America, Canada, Mexico, Brazil, South Africa, Algeria, Zambia, Kenya, Zambia, Cameroon, Ethiopia, Uganda, Madagascar, Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Uzbekistan, Tajikistan, Bangladesh, India, Pakistan, Lebanon, Iraq, Egypt, Qatar, Yemen, Oman, Turkey, Saudi Arabia, UAE and some other countries.

PRODUCTS

Paint Mixer Coating Mixing Machine Solutions

Enhanced Efficiency and Productivity

Paint mixing machines significantly boost productivity compared to manual mixing methods. Manual mixing is time-consuming, labor-intensive, and prone to human error, leading to inconsistencies in batch consistency and color accuracy. Automated mixers, on the other hand, can handle larger batches in significantly less time, freeing up human resources for other crucial tasks. This increased throughput translates directly into higher production volumes and greater profitability.

Moreover, the precision of automated systems ensures consistent mixing speeds and durations, leading to a more uniform product. This consistency reduces the risk of rejects and rework, further enhancing overall efficiency and lowering production costs. The programmable nature of many machines allows for the precise replication of successful batches, eliminating the guesswork and variability associated with manual mixing.

Superior Product Quality and Consistency

One of the most significant advantages of using paint mixer and coating mixing machine solutions is the superior product quality they deliver. Manual mixing, even with meticulous attention to detail, often fails to achieve the perfect dispersion of pigments and additives. This can result in variations in color, texture, and viscosity across different batches. Automated mixers, equipped with high-shear mixers or other advanced mixing technologies, ensure uniform dispersion, leading to consistent product quality across all batches.

This consistency is crucial for maintaining brand reputation and meeting customer expectations. In industries with stringent quality control requirements, such as automotive coatings or aerospace applications, the use of advanced mixing machines is not merely beneficial, but essential for ensuring product reliability and performance. The elimination of human error in the mixing process ensures that each batch meets the exact specifications defined.

Cost Savings and Reduced Waste

While the initial investment in a paint mixer and coating mixing machine might seem significant, the long-term cost savings are substantial. Reduced labor costs, minimized waste due to consistent mixing, and improved product quality all contribute to a positive return on investment. Automated systems often feature precise dispensing mechanisms, reducing material waste by accurately measuring and delivering the required amounts of each ingredient.

Furthermore, the improved consistency reduces the likelihood of rejected batches, saving on raw materials and labor costs associated with rework. This efficient use of resources contributes not only to the bottom line but also to a more sustainable manufacturing process. The reduction in waste also minimizes the environmental impact associated with the disposal of faulty products.

Safety and Environmental Considerations

Many paints and coatings contain volatile organic compounds (VOCs) or other hazardous materials. Manual mixing of these materials increases the risk of exposure for workers. Automated mixing machines significantly reduce this risk by minimizing human interaction during the mixing process. The enclosed nature of many machines also helps to contain fumes and dust, creating a safer working environment.

Beyond worker safety, the improved efficiency and reduced waste contribute to a smaller environmental footprint. Less material waste means less disposal and reduced energy consumption during the manufacturing process. Many modern machines also incorporate features designed to minimize energy consumption, further enhancing their environmental benefits.

SUBSCRIBE

INQUIRY