- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

ABOUT

TGM Machine is a leading supplier in the field of chemical machine industry. We are a group company with 19 years of industry experience. We located in Guangdong and Hunan province.

Our main products include kinds of mixer, bead mill, reactor, filter and filling machine. Our machines are widely use to make different products, for example paints, coatings, putty, inks, pigments, dyes, thinner, hardener, emulsions, varnish, glues, adhesives, resins, RTV, HTV, silicone sealant, MS sealant, PU sealant, lithium battery, electronic slurry&pastes, pulps, grease, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on. We are professional supplier for one stop solution of your full lines too.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions, to meet your various standards and non standard equipment procurement needs. We integrate design, development, production, sales, installation and training together. In addition, we have obtained kinds of certificates, such as ISO9001, ATEX, CE and so on.

Till now we have customers from more than 60 countries, such as UK, Spain, Italy, Germany, Netherlands, Bulgaria, Romania, Serbia, Cyprus, Russia, Belarus, Ukraine, America, Canada, Mexico, Brazil, South Africa, Algeria, Zambia, Kenya, Zambia, Cameroon, Ethiopia, Uganda, Madagascar, Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Uzbekistan, Tajikistan, Bangladesh, India, Pakistan, Lebanon, Iraq, Egypt, Qatar, Yemen, Oman, Turkey, Saudi Arabia, UAE and some other countries.

PRODUCTS

Machine Requirement of Making Silicone Sealant And The Function of the Machine

Core Equipment Configuration List

Raw Material Processing Unit

-

Vacuum Mixer: Used for strong mixing of silicone-based materials and fillers, with a vacuum degassing function (to avoid bubble residues before curing for acidic adhesives). It is recommended to choose a stainless steel model with double-layer stirring paddles and a temperature control system, with a capacity selected based on output requirements (1-5 tons).

-

Three-Roller Mill: Homogenizes the mixed paste to eliminate particle agglomeration and ensure the leveling property of acidic adhesives. The roller material needs to be resistant to acid corrosion (e.g., tungsten carbide coating).

Reaction and Mixing Unit

-

Planetary Mixer: Used for viscosity adjustment of the gel before filling, may integrate a vacuum system for further degassing. A double planetary structure is recommended, with adjustable speeds from 0 to 60 rpm, with power matched to the viscosity of the gel (acidic gels typically have higher viscosity than neutral gels).

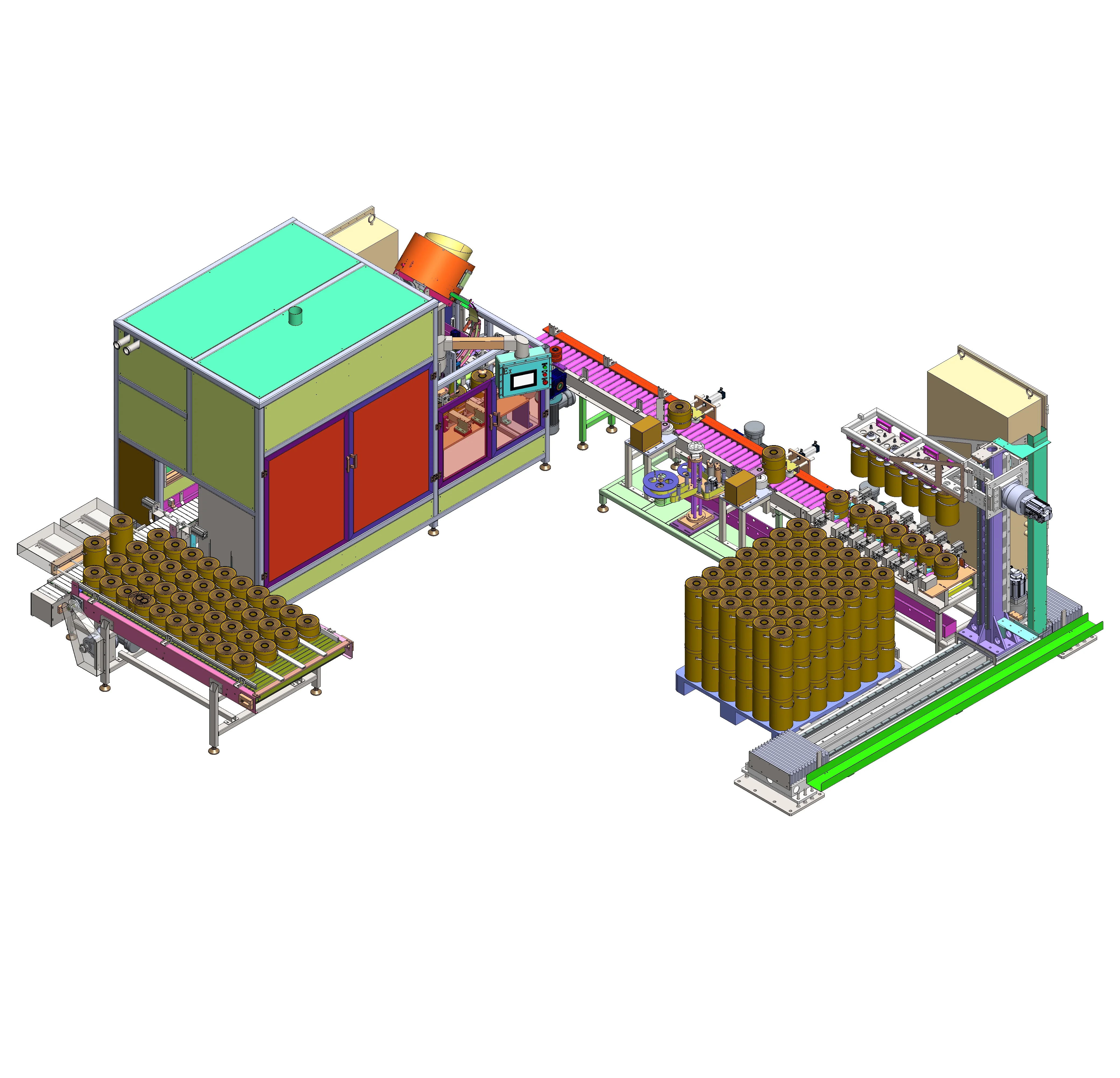

Filling and Packaging Unit

-

Semi-Automatic Piston Filling Machine: Specifically designed for filling acidic adhesives into hard tubes (aluminum/plastic). Contact parts must resist acetic acid corrosion (e.g., PTFE coating). Filling accuracy should be ±1%, with a speed of 25-40 tubes/minute, supporting various specifications of 150-500ml.

-

Labeling and Packing Equipment: Semi-automatic labeling machine + manual stacking. Labels should clearly mark corrosion warning labels for acidic adhesives (compliant with GHS standards).

Auxiliary Systems

-

Vacuum Degassing Unit: Configured in segments during mixing, reaction, and filling to ensure the final product is free from bubble defects (bubbles can lower the weather resistance of acidic adhesives).

-

Exhaust Gas Treatment System: The production of acidic adhesives releases trace amounts of acetic acid vapor. Therefore, it requires a caustic spraying tower or activated carbon adsorption device to comply with European and American environmental regulations.

-

Laboratory Testing Equipment: Includes pH testers (to monitor the acidic environment), tensile testing machines (to test adhesive strength after curing), and accelerated aging boxes (to simulate weather resistance).

SUBSCRIBE

INQUIRY