- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

ABOUT

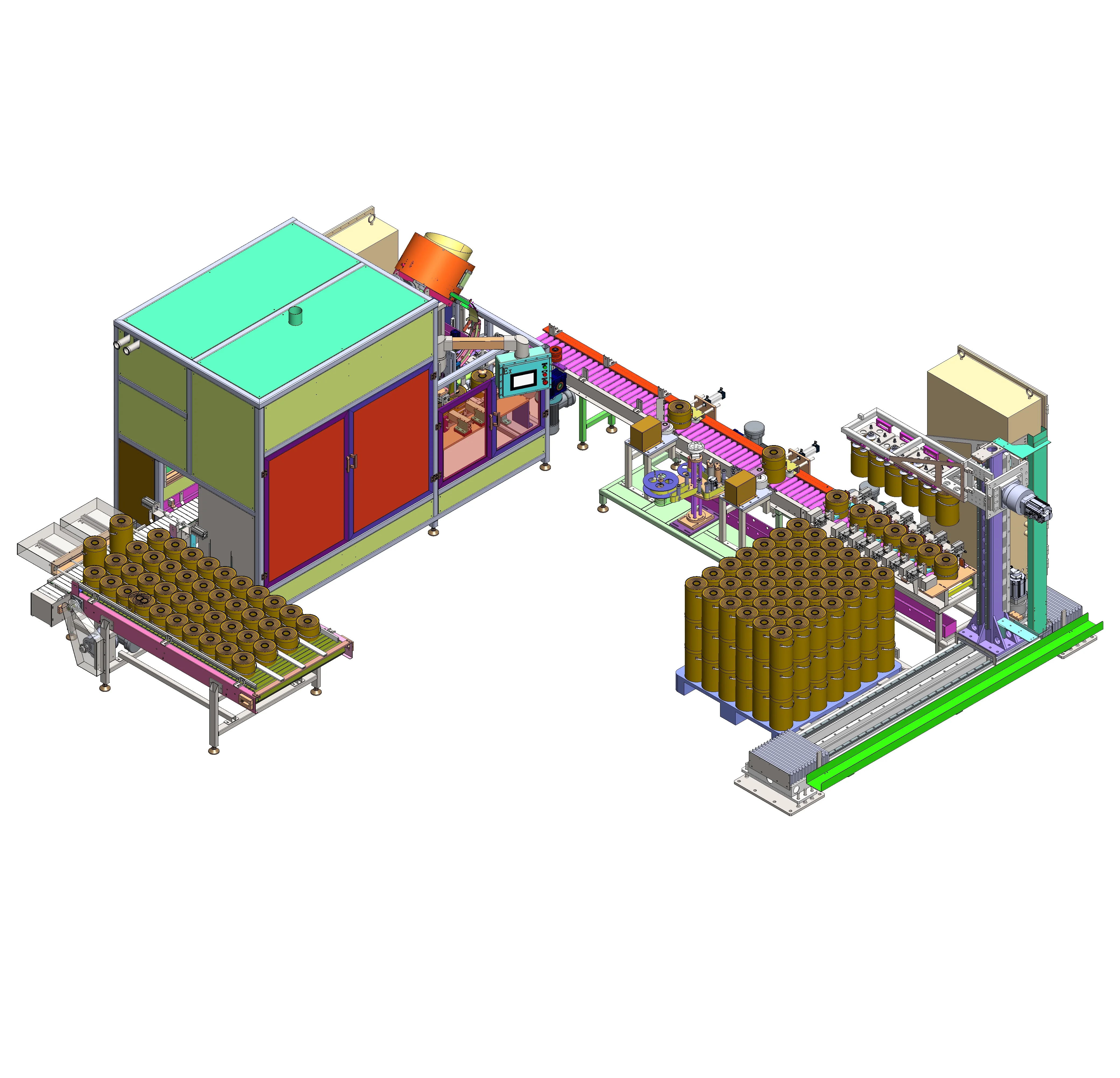

TGM Machine is a leading supplier in the field of chemical machine industry. We are a group company with 19 years of industry experience. We located in Guangdong and Hunan province.

Our main products include kinds of mixer, bead mill, reactor, filter and filling machine. Our machines are widely use to make different products, for example paints, coatings, putty, inks, pigments, dyes, thinner, hardener, emulsions, varnish, glues, adhesives, resins, RTV, HTV, silicone sealant, MS sealant, PU sealant, lithium battery, electronic slurry&pastes, pulps, grease, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on. We are professional supplier for one stop solution of your full lines too.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions, to meet your various standards and non standard equipment procurement needs. We integrate design, development, production, sales, installation and training together. In addition, we have obtained kinds of certificates, such as ISO9001, ATEX, CE and so on.

Till now we have customers from more than 60 countries, such as UK, Spain, Italy, Germany, Netherlands, Bulgaria, Romania, Serbia, Cyprus, Russia, Belarus, Ukraine, America, Canada, Mexico, Brazil, South Africa, Algeria, Zambia, Kenya, Zambia, Cameroon, Ethiopia, Uganda, Madagascar, Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Uzbekistan, Tajikistan, Bangladesh, India, Pakistan, Lebanon, Iraq, Egypt, Qatar, Yemen, Oman, Turkey, Saudi Arabia, UAE and some other countries.

PRODUCTS

Learn How to Achieve Seamless Glass Assembly with High Quality Adhesives for Optimal Performance and Long Lasting Results in Every Application

In the realm of modern construction and design, the need for innovation and seamless integration has never been greater. Whether it’s for architectural marvels or functional everyday items, glass assembly has emerged as a dynamic field where aesthetic beauty and practical application converge. One of the most critical components in achieving seamless and effective glass assembly is the use of high-quality adhesives. The article titled “Learn How to Achieve Seamless Glass Assembly with High Quality Adhesives for Optimal Performance and Long Lasting Results in Every Application” delves deep into this subject, providing valuable insights that are essential for anyone involved in glass manufacturing, crafting, or installation. This exploration not only covers the basic concepts of glass assembly and adhesive types but also discusses performance metrics and best practices for ensuring durability and efficiency.

Understanding Glass Assembly

Glass assembly is a process that involves the joining of glass pieces to create a cohesive structure. This can range from simple glazing applications in windows to complex installations in skyscrapers and facades. The importance of achieving a seamless assembly cannot be overstated, as it directly affects the overall appearance and functionality of a project. Seamless glass assembly enhances the visual appeal, ensuring that the end product appears as a unified entity rather than a collection of separate components. This is particularly significant in artistic applications, where the glass itself is a canvas that contributes to the entire aesthetic of the installation.

Moreover, glass assembly is not merely an aesthetic consideration; it also has practical implications. Properly assembled glass structures can improve energy efficiency, reduce noise infiltration, and enhance safety measures. Thus, the techniques and materials used in glass assembly play a pivotal role in delivering both stunning visual results and optimal performance for years to come.

The Role of High-Quality Adhesives

At the heart of seamless glass assembly lies the adhesive used to bond the glass pieces together. High-quality adhesives are crucial for ensuring that the joints are not only visually appealing but also robust and reliable. Different types of adhesives are available, each designed for specific applications and conditions. For instance, silicone adhesives are commonly used for their flexibility and ability to withstand varying temperatures, while structural adhesives provide strength and durability in load-bearing applications.

Another important factor is the adhesive's transparency. In glass assembly, the aesthetic qualities are paramount, and the adhesive used should be clear or exhibit minimal visibility to maintain the seamless appearance of the finished product. This means that careful selection of adhesive type and formulation is vital to avoid unsightly bonding lines that could detract from the overall design.

Performance Metrics for Adhesives

When selecting the right adhesive for glass assembly, several performance metrics must be taken into account. These include shear strength, tensile strength, curing time, and resistance to environmental factors such as UV light and moisture. Shear strength refers to the adhesive's ability to resist forces that can cause the glued materials to slide apart, which is particularly important for vertical installations such as glass facades. Conversely, tensile strength measures the adhesive's resistance to forces that pull the materials apart, ensuring that the bond remains intact under stress.

Curing time is another critical factor; an adhesive that cures too slowly may prolong project timelines, while one that cures too quickly may not allow sufficient working time for proper alignment of the glass components. Additionally, durability against environmental factors, including resistance to UV degradation and moisture penetration, ensures that the glass assembly retains its integrity over time, resulting in long-lasting performance.

Best Practices for Seamless Glass Assembly

To achieve optimal results in glass assembly using high-quality adhesives, several best practices should be followed. Firstly, it is essential to prepare the surfaces of the glass thoroughly. Cleaning the glass to remove dust, oils, and other contaminants is crucial for ensuring strong adhesion. Even minor impurities can significantly weaken the bond, leading to eventual failure.

Secondly, the application of adhesive should be uniform and controlled. This can be achieved through the use of precise dispensing tools that allow for an even bead of adhesive to be applied. Taking time to position the glass correctly during assembly is also vital, as any misalignment can create stress points that compromise the integrity of the assembly.

Lastly, it’s important to adhere to the manufacturer’s instructions regarding curing times and environmental conditions. Ensuring that the adhesive is allowed to cure in optimal conditions will maximize its performance capacity. Regular checks during the installation process can help identify potential issues early, making it easier to address them before they develop into significant problems.

Conclusion

In conclusion, the art of seamless glass assembly is a nuanced process that hinges on the effective use of high-quality adhesives. By understanding the fundamentals of glass assembly, selecting the right adhesive, and adhering to best practices, one can achieve not only visually stunning results but also structures that stand the test of time. The insights provided in the article “Learn How to Achieve Seamless Glass Assembly with High Quality Adhesives for Optimal Performance and Long Lasting Results in Every Application” serve as an invaluable resource for professionals and enthusiasts alike, guiding them toward achieving their glass assembly goals with confidence and expertise.

SUBSCRIBE

INQUIRY