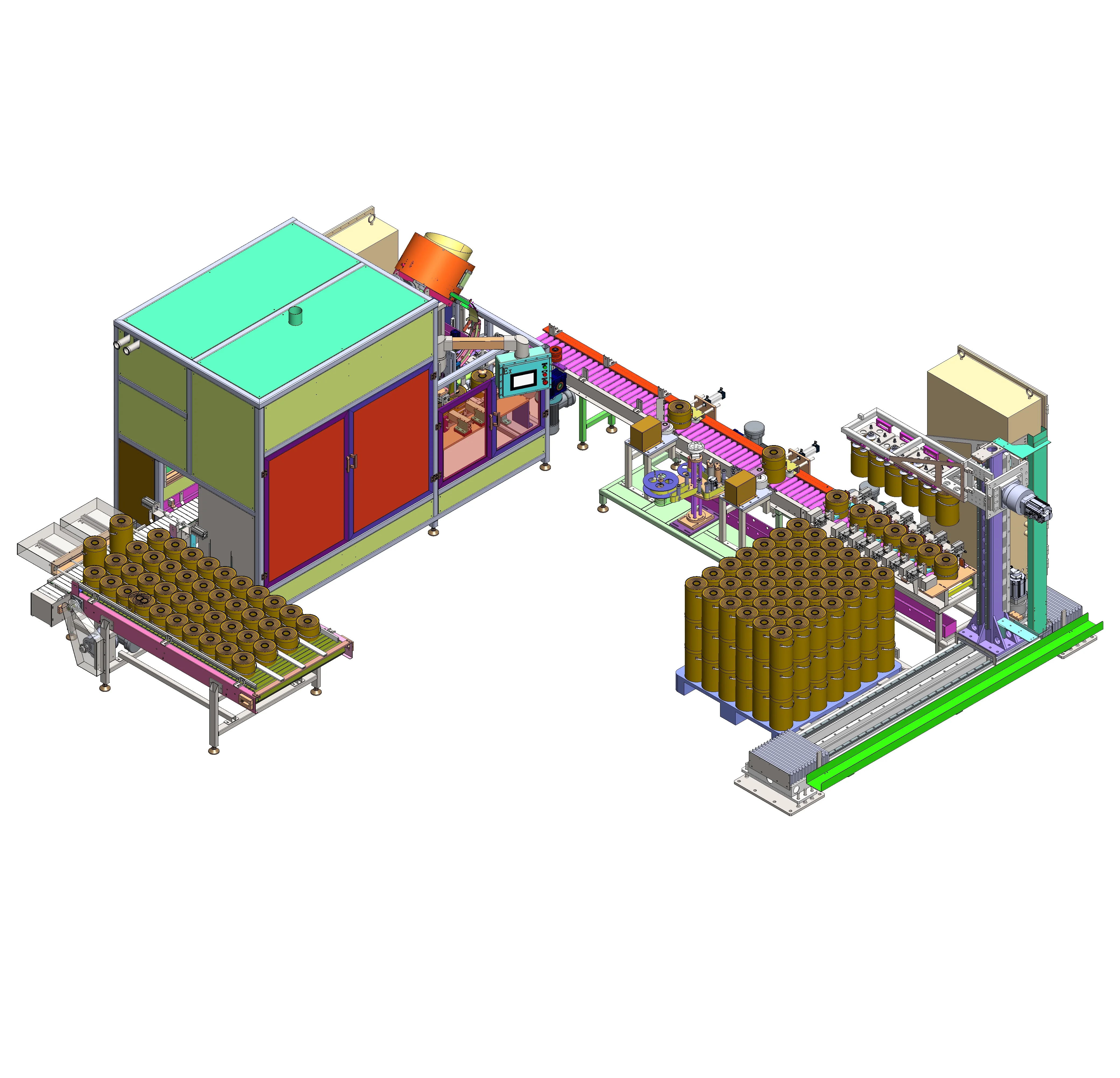

- SILICONE SEALANT PRODUCTION LINE

- EMULSION / RESIN PRODUCTION LINE

- ADHESIVE PRODUCTION LINE

- HOT MELT PRODUCTION LINE

- PAINTS & COATINGS PRODUCTION LINE

- POWDER COATING PRODUCTION LINE

- Reactor/Mixing Kettle

- Dispersing Machine

- Emulsifying Machine

- Filters

- Filling& Capping Machine

- Mixing/Storage Tank

- Lab Machine

- Accessories

ABOUT

TGM Machine is a leading supplier in the field of chemical machine industry. We are a group company with 19 years of industry experience. We located in Guangdong and Hunan province.

Our main products include kinds of mixer, bead mill, reactor, filter and filling machine. Our machines are widely use to make different products, for example paints, coatings, putty, inks, pigments, dyes, thinner, hardener, emulsions, varnish, glues, adhesives, resins, RTV, HTV, silicone sealant, MS sealant, PU sealant, lithium battery, electronic slurry&pastes, pulps, grease, silicon dioxide, liquid rubber, pesticide, liquid fertilizer, disinfectant, detergent, gel, lotions, shampoo, body wash, liquid soap, hand sanitizer, liquid wash, nail polish, creams, and so on. We are professional supplier for one stop solution of your full lines too.

We have professional R&D design team, strong technical support, skilled production team, reliable after sales service, flexible customized solutions, to meet your various standards and non standard equipment procurement needs. We integrate design, development, production, sales, installation and training together. In addition, we have obtained kinds of certificates, such as ISO9001, ATEX, CE and so on.

Till now we have customers from more than 60 countries, such as UK, Spain, Italy, Germany, Netherlands, Bulgaria, Romania, Serbia, Cyprus, Russia, Belarus, Ukraine, America, Canada, Mexico, Brazil, South Africa, Algeria, Zambia, Kenya, Zambia, Cameroon, Ethiopia, Uganda, Madagascar, Malaysia, Indonesia, Singapore, Vietnam, Thailand, Kazakhstan, Uzbekistan, Tajikistan, Bangladesh, India, Pakistan, Lebanon, Iraq, Egypt, Qatar, Yemen, Oman, Turkey, Saudi Arabia, UAE and some other countries.

PRODUCTS

Discover the Ultimate Guide to Choosing the Right Glass Adhesive for Your Home Improvement Projects and DIY Repairs with Expert Tips

When it comes to home improvement projects and DIY repairs, choosing the right materials is paramount to achieving lasting results. Among the plethora of materials available, glass stands out due to its versatility and aesthetic appeal. However, the effectiveness of glass projects greatly depends on the adhesive used. In “Discover the Ultimate Guide to Choosing the Right Glass Adhesive for Your Home Improvement Projects and DIY Repairs with Expert Tips,” we delve into the nuances of selecting the ideal adhesive for glass. This article aims to equip readers with the essential knowledge to make informed decisions, ensuring successful projects every time.

Understanding Glass Adhesives

Before diving into the specific types of adhesives available for glass, it is imperative to understand what makes glass adhesive unique. Glass, often considered a challenging material to bond, requires specially formulated adhesives that can handle its non-porous surface and ensure strong adhesion over time. Most general-purpose adhesives fail to provide the necessary grip or flexibility that glass projects demand. Additionally, some adhesives may become brittle or discolored, compromising both the structural integrity and appearance of your work.

To address this, manufacturers have developed a range of adhesives specifically for glass. These adhesives not only bond well to glass but are also designed to remain clear and durable, making them ideal for both visible projects and repairs. However, understanding your specific project’s requirements—such as exposure to moisture, temperature fluctuations, or the need for flexibility—is crucial for choosing the right adhesive.

Types of Glass Adhesives

Glass adhesives come in various forms, each suited to different applications. The primary types include epoxy, cyanoacrylate (super glue), silicone, and polyurethane adhesives. Each type has distinct properties, advantages, and disadvantages that can greatly impact your project.

Epoxy adhesives are known for their strong bonding capabilities and resistance to heat and chemicals, making them suitable for projects that require structural integrity. They often come in two parts—a resin and a hardener—that need to be mixed before application. This can be time-consuming, but the durability they offer is often worth the wait, especially for permanent fixtures.

Cyanoacrylate adhesives, commonly referred to as super glue, are popular for quick fixes due to their fast-setting nature. They work well for small repairs and light-duty applications but may not be suitable for larger projects where a stronger bond is required. Moreover, they can become brittle over time, especially in environments with high humidity or temperature changes.

Silikone adhesives provide excellent flexibility, making them ideal for projects that involve movement or expansion, such as between glass panels or glass and metal. They are water-resistant and can handle different environmental conditions, although they may not provide the strongest bond for heavy-duty applications.

Polyurethane adhesives are robust and versatile, providing strong bonds that are resistant to moisture and can also handle differing materials joining glass to wood or metal. However, they can be messy to work with and require careful handling, as they can expand and foaming during the curing process.

Choosing the Right Adhesive for Your Project

Selecting the appropriate adhesive for your glass project involves evaluating several factors. First and foremost, consider the nature of the project. Are you making decorative items, repairing broken glass, or installing glass fixtures? The requirements for a decorative piece will vastly differ from those needed for structural installations.

Next, assess the environment where the adhesive will perform. Will it be exposed to moisture, extreme temperatures, or direct sunlight? For outdoor applications or areas with high humidity, a silicone or polyurethane adhesive may be the best choice due to their resistance to environmental factors.

Moreover, consider the time you have available for your project. If you’re looking for a quick solution, cyanoacrylate adhesives can be a great choice. However, for strong, durable bonds that will stand the test of time, you may need to invest in the labor-intensive mixing of epoxy adhesives.

Expert Tips for Application

Once you have chosen the right adhesive for your glass project, following proper application techniques is vital for achieving successful results. Here are some expert tips to guide you:

1. **Surface Preparation**: Ensure that all surfaces are clean, dry, and free of any dust or grease. Use isopropyl alcohol or a glass cleaner for wiping the surfaces before application to maximize adhesive performance.

2. **Follow Instructions**: Each adhesive comes with specific instructions, including recommended curing times and conditions. Following these can greatly impact the adhesive's effectiveness and longevity.

3. **Apply Evenly**: Use a small brush or a precise applicator to apply a thin, even layer of adhesive. This prevents overflow and ensures that the adhesive penetrates any small gaps effectively.

4. **Secure & Wait**: If possible, clamp or secure the pieces in place while the adhesive cures. This will help in maintaining alignment and ensure a stronger bond once fully set.

Final Thoughts

Choosing the right glass adhesive is crucial for the success of your home improvement projects and DIY repairs. With so many options available, understanding the different types of adhesives and their specific applications is essential. Evaluate your project needs carefully, make informed choices, and employ proper application techniques to ensure beautiful, lasting results. Whether you are a seasoned DIY enthusiast or a beginner, this ultimate guide serves to simplify the adhesive selection process, paving the way for successful glass projects in your home.

SUBSCRIBE

INQUIRY